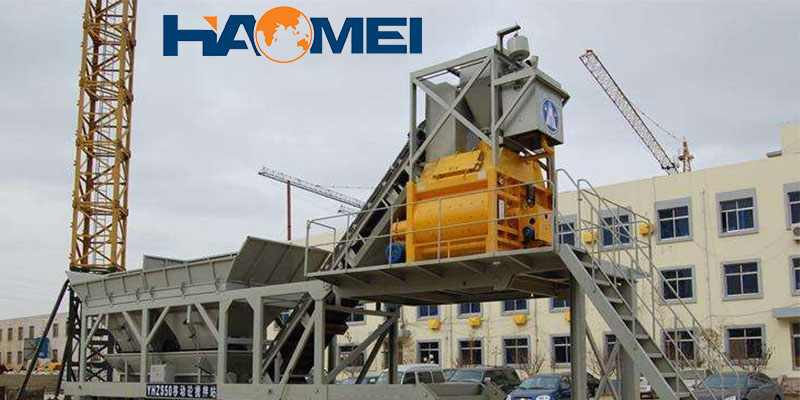

Brief Introduction:This is about key points of daily maintenance of a ready mix concrete batching plant.

Daily maintenance after work of a ready mix concrete batching plant

1. Eliminate mud from the distributor belt and the rollers. Mud sticking onto rollers will make rollers slippery and lead to inclination of belt.

2. Check whether the engine oil level is too low, in which case the oil tank needs a refill.

3. Check the air service unit of the ready mix concrete plant. Make sure the lubricant is sufficient any time for excellent sealing and lubricating.

4. The concrete mixer must be cleaned, and no concrete remains should be allowed.

Key points in ready mix concrete batching plant maintenance

1. Gas leaking in the air pipeline. Poor sealing of pipeline connections tend to lead to gas leakage. It’s not like that this problem is hard to be found out or solved. Many people just refuse to consider it as a serious problem, for it does not affect normal operation of a concrete batching plant. However, accumulated gas leakage will increase on and off times of the air compressor, which will increase energy consumption correspondingly. Thus it’s necessary to work out the problem once noticing it.

2. Grease model selection. Generally, No. 1 lithium base grease can be used at 10 degrees and No. 2 lithium base grease is used at 10 degrees or more. This is to ensure the lubrication and wear resistance of lithium base grease. Other models may not function as a lithium base grease.

3. Journal sticking of the concrete mixer. Common as it is, this problem can be avoided simply by prompt cleaning of concrete on the main shaft. Accumulated concrete on the shaft will first lead to extra energy consumption and then a smoldering tank.

4. Check whether electrical parts are over heated or giving off unusual noises, and whether the indicator and the signal system are normal.

5. In winter all parts that get contact with water must be cleaned in time, or else ice may come into being, damaging components of a ready mix concrete batching plant or preventing them from normal running.